Application: This system is employed in biosafety laboratories to immerse items in liquid for decontamination, thereby preventing cross-contamination between different areas during item transfer.

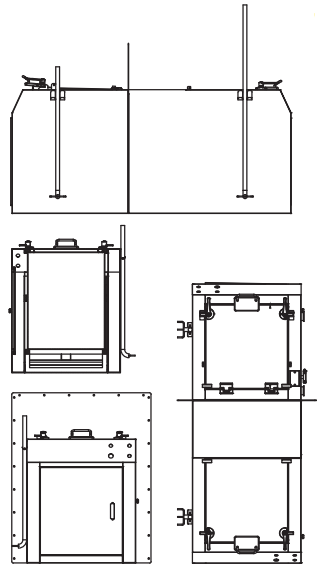

Composition: The system comprises the main body, internal carriage transfer system, control system, signal output and alarm system, disinfection and drainage outlet.

Material: The inner trough is made of 316L stainless steel, while the exterior is 304 stainless steel.

Structure: Fully welded inner cavity, with a double airtight door interlock structure.

Sealability: Double airtight doors with pressure sealing and liquid sealing.

Installation: User-friendly installation, closely connected to the wall panel.

External dimensions: 1803*W703*H800mm (excluding rake, hook, and partition sizes)Single-side aqueduct opening size: L500*W500mm

2.Materials: The cover plate and the main body of the aqueduct are welded with national standard T=3.0mm 316L brushed stainless steel plate, while the external body is welded with national standard T=2.0mm 304 brushed stainless steel.

3.Doors: No mechanical interlocking on both sides; instead, an electromagnetic lock is fitted on each of the front and back.

4.Equipped with a hydraulic linkage. When the cover plate opens, it causes the hydraulic linkage to rotate. The cover plate movement has a limit device, and the cover plates on both sides are electromagnetically interlocked.

5.Equipped with two quick-fit disinfection ports for VHP fumigation connection.

6.Equipped with a quick connector on the drainage pipe and a ball valve as a stop valve.

7.Equipped with 2 rakes, which are mounted on the side hooks.

8.Control: a. Control principle: When powered, indicators on both sides are illuminated. Both cover plates are electromagnetically interlocked, preventing simultaneous opening. A buzzer sounds an alarm if a cover plate remains open for an extended period. The soaking time for each side can be set via the touchscreen. Once the set time elapses, the cover plate can be opened by pressing the door open button once the set time elapses. If the set time has not been reached, pressing the door open button will not allow the cover plate to be opened. The internal liquid level is monitored by a sensor, and a low liquid level triggers a buzzer alarm (sensor detectable liquid level range: 240mm, see figure for details). The level meter has a signal output that can transmit signals to the BMS platform, providing feedback on liquid levels. Additionally, it emits an alarm signal when the liquid level falls below the minimum. The LCD screen displays the alarm information. b. Control mode: LCD screen and PLC control. c. Configuration: 2 emergency stops, 2 buzzers, 2 power indicators, 2 door open buttons, 1 LCD screen, 1 liquid level sensor, and 1 set of control systems.

9.Appearance: Ensures a neat appearance.

Consultation