▉ Product features

Compact structure, easy installation and replacement

The Puricel II frame is made of aluminum extruded profile, and the imported phosphorus-free polyurethane adhesive is used to seal the waterproof and flame-retardant fiberglass filter element which is spaced by hot melt adhesive, supplemented by the surface protective mesh, sealing gasket and other compo-nents. It features a compact structure, small and light, easy installation and replacement.

Comprehensive leak testing to ensure no leaks

The industry's advanced environmental-friendly water-based aerosol leak detection platform is used for testing without secondary pollution, to ensure that each piece of filter is leak-free.

Testing efficiency according to EN1822

According to EN1822 standard, the United States PMS laser particle counter and PSL test particles are used to test the efficiency of the filter using the most penetrating particle size (MPPS) method to ensure that the filter efficiency meets requirements.

Separator-free structure, with low resistance and good energy saving

The specially designed hot melt adhesive is used to separate the HEPA filter paper to ensure the same and reasonable spacing between the filter paper, which can make full use of the filter paper to achieve uniform air speed and low resistance.

Strictly selected materials, with very low chemical volatilization

All components are made of very low chemical volatile materials to meet the requirements of conventional cleanrooms for air filtration equipment.

Non-continuous spraying technology with low resistance; "V" shaped channel, with low resistance and long service life;

automatic staging to flexibly adjust pleat height and width for demand.

▉ Specifications

▉ Dimensions

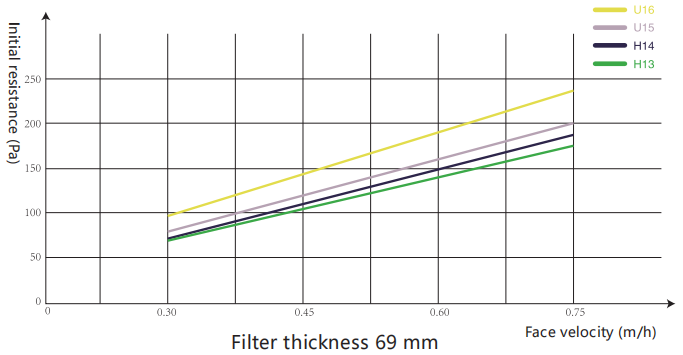

▉ Initial resistance - air speed relationship graph

▉ Dimensions

Maximum deviation range of resistance: ±15%

Non-standard dimensions can be customized according to customer needs

▉ Naming rules

▉ Drawing

Consultation