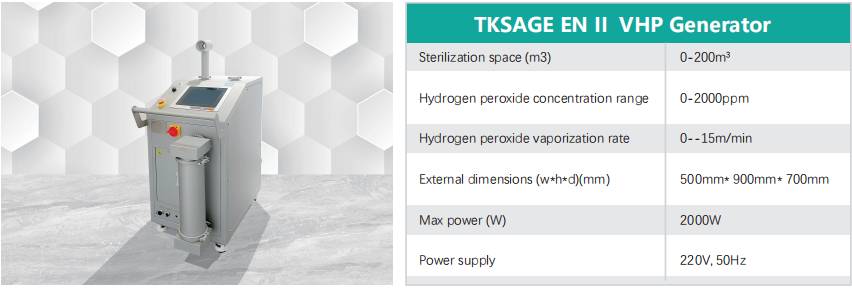

For surface disinfection and low-temperature surface sterilization

Applications of TKSAGE-EN II VHP generator

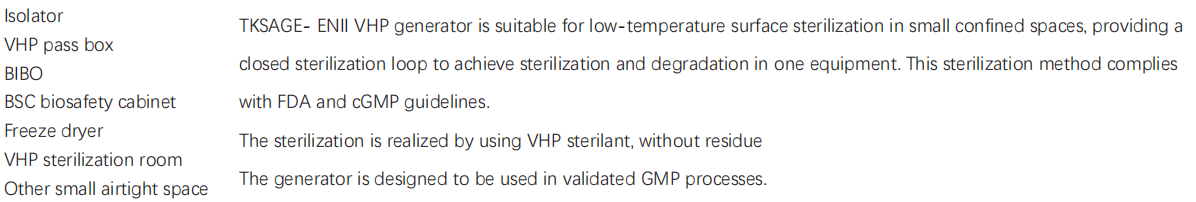

Principle of TKSAGE- EN II VHP generator

Principle of TKSAGE- EN II VHP generator

TKSAGE-EN uses low-temperature flash vaporization technology to achieve complete vaporization of hydrogen peroxide;

The process saturation control technology is adopted to realize noliquefaction and no condensation in the whole process of sterilization;

The process monitoring parameters include: temperature, relativehumidity,hydrogen peroxide concentration and vapor saturation;

The adjustment parameters include: flash temperature, circulating air volume, and peristaltic pump injection rate;

The safety control parameters include: hydrogen peroxide concentration, saturation and hydrogen peroxide residual concentration;

The VHP generator is integrated with the catalytic degradation, making the sterilization more convenient and faster.

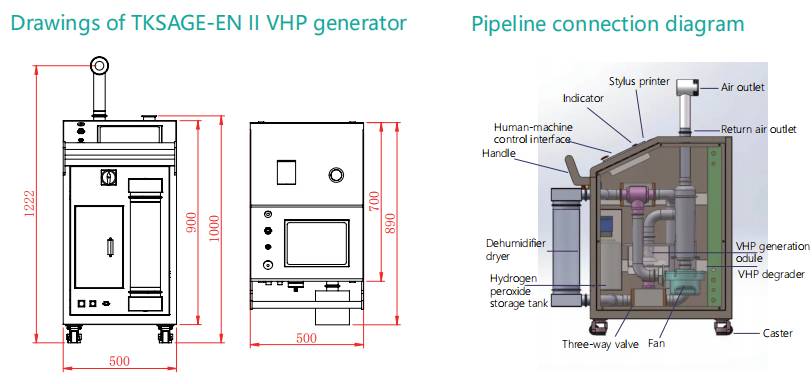

Pipeline connection

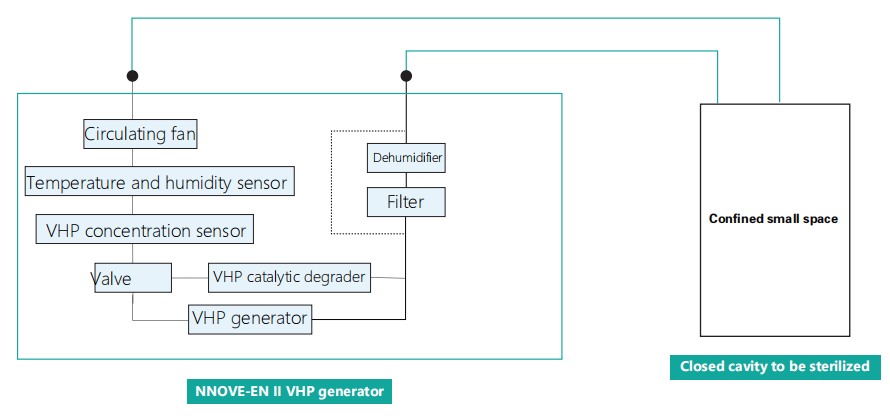

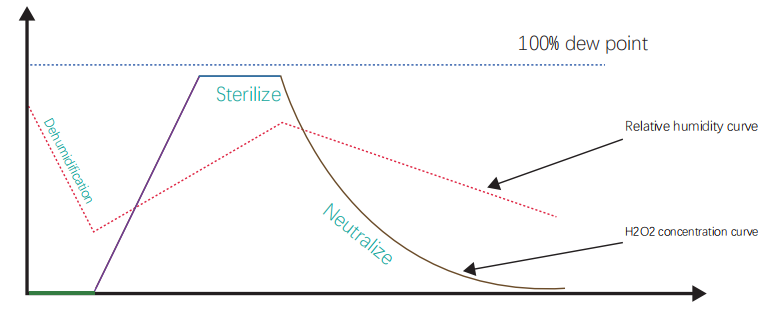

VHP sterilization curve

The sterilization process is divided into four stages: start, balance, sterilize and degrade

Start: Before sterilization starts, the equipment automatically determines whether the sterilization conditions meet sterilization start requirements, i.e.: temperature>15°C, 40%< RH%<60%; automatic dehumidification will start if the humidity is high;

Balance: The VHP generator starts to produce hydrogen peroxide vapor and circulates it between the cavity and the equipment until it reaches a preset concentration or saturation level;

Sterilize: The equipment starts to record the sterilization effect until the preset sterilization LOG value is reached.

Degrade: At the end of the sterilization process, the equipment automatically enters the VHP degradation stage, which starts to catalyze the degradation of the hydrogen peroxide vapor inside the equipment and the chamber until it

reaches the set hydrogen peroxide concentration.